Your benefits

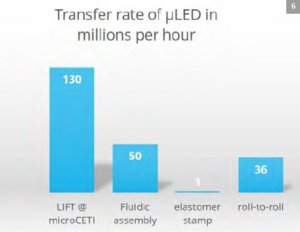

The display market is subject to constant change. New display technologies based on MicroLEDs are considered to have high potential. Smartwatches are also predicted to be equipped with MicroLED displays in 2024 and premium smartphones in 2027. As well as the increasing usage of VR (Virtual Reality) and AR (Augmented Reality) glasses will increase the demand for high-resolution MicroLED displays.

As a competent and reliable partner, we stand at your side to respond now to tomorrow’s requirements and support the transfer of your MicroLED chips as part of our laser contract manufacturing service.

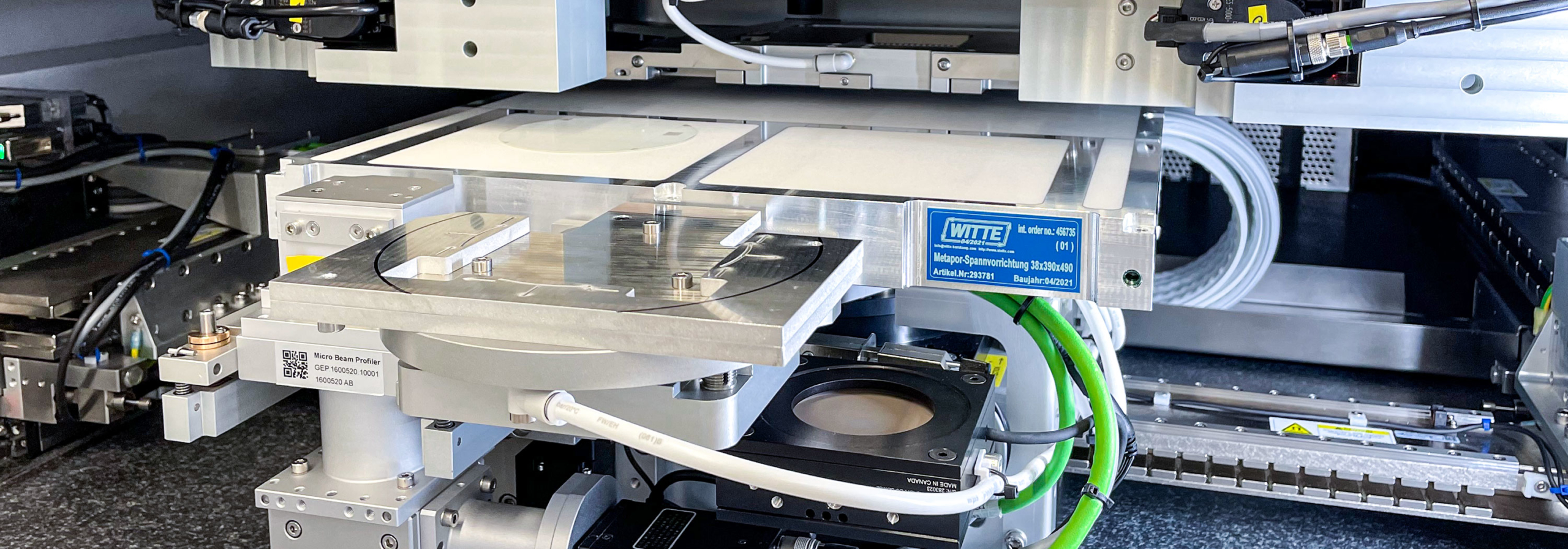

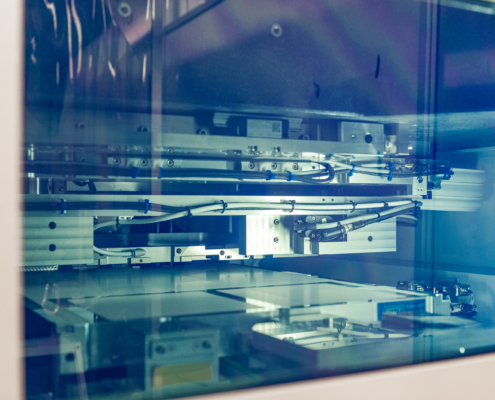

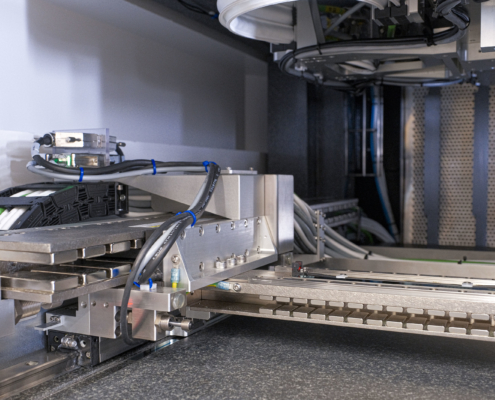

From creating initial prototypes to small to medium batches: as the world’s first manufacturer of a MicroLED transfer module for mass production, we are the ideal partner for producing your MicroLED displays with many years of experience in the field of laser technologies.

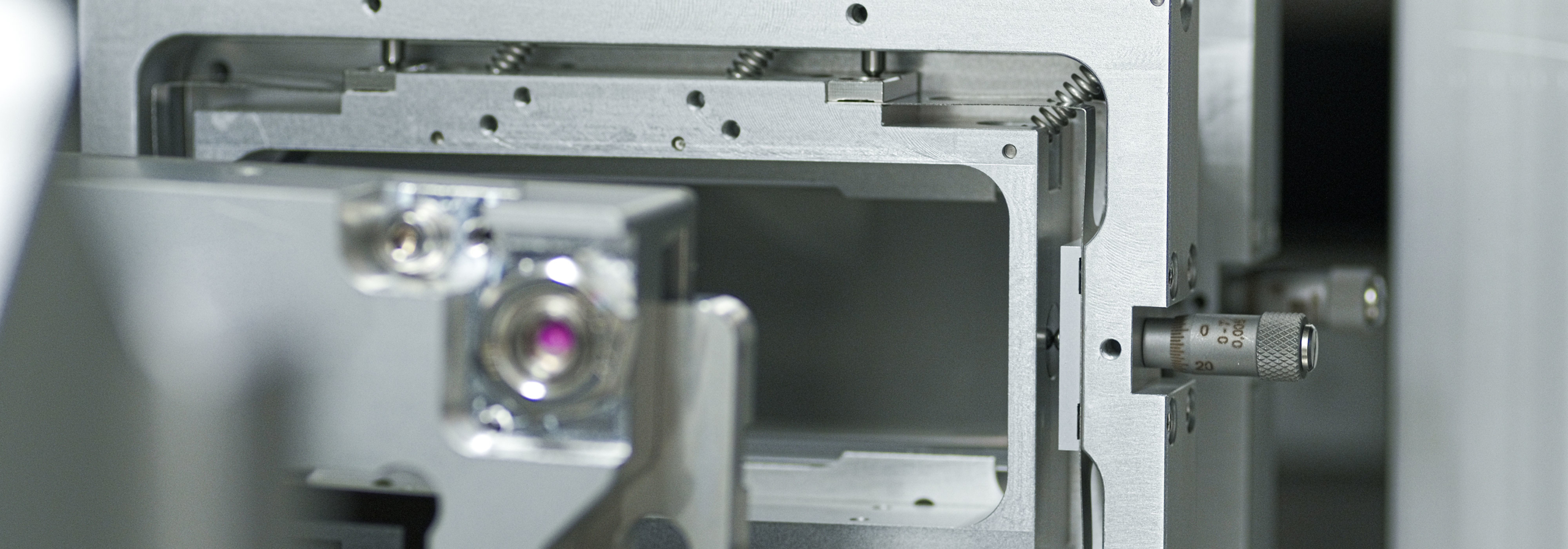

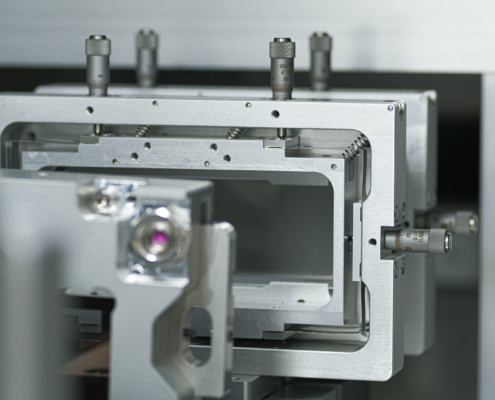

Besides the LIFT process, we are able to adopt the laser Lift-Off as well as customer-specific trimming processes or a combination of those.

Application examples

- Transfer of MicroLEDs with the help of the LIFT method

- Laser trimming

- Laser Lift-Off of substrates

Application area

- Display industry

- Semiconductor industry

- Research and development

Materials that can be processed include

- Glass including sapphire

- Glass without sapphire

- Polymer

Additional technical information

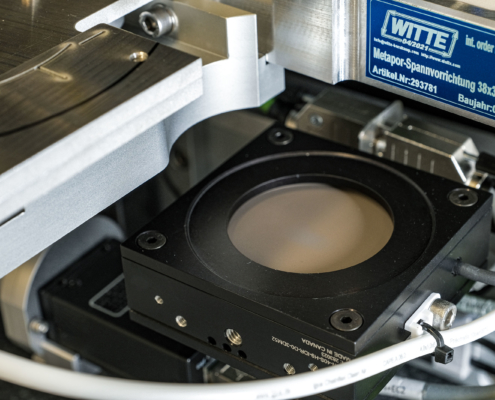

- Chip size up to 5 µm

- Street width up to 5 µm

- Position accuracy of less than 1 μm

- Distance between the carrier substrate and receiver substrate up to +50 µm

- Suitable for MicroLED, MiniLED, and LED

- Usage of different laser sources